-

How to prevent static electricity accumulation in plastic toolboxes

2025-09-15Plastic toolboxes, especially those made of insulating materials such as polyethylene and polypropylene, have high surface resistance and are prone to static electricity accumulation due to friction, contact separation, etc., which may pose a safety hazard to electronic components and flammable and explosive materials stored inside. Preventing the accumulation of static electricity requires starti

-

What is the heat treatment process for electronic scale molds

2025-09-08The heat treatment process of electronic scale molds needs to be combined with their core requirements - high dimensional stability (to avoid deformation affecting weighing accuracy), moderate hardness (to balance processability and wear resistance), low internal stress (to prevent long-term use cracking), and also need to be adapted to commonly used mold materials (such as pre hardened plastic mo

-

How to isolate charged objects in plastic toolboxes

2025-09-01Plastic toolboxes can isolate charged objects, relying on the electrical insulation properties of the plastic itself, combined with structural design and usage standards to form a complete protection. The isolation principle and implementation method can be developed from three dimensions: material, structure, and usage, as follows:

-

Why can toolbox molds achieve batch standardized production

2025-08-25The core reason why the tool box mold can realize batch standardized production is that the "stereotyped characteristics" of the mold itself are compatible with the "process synergy" of the modern manufacturing system - the structure, size and appearance of the tool box are fixed as a unified standard through the mold, and the batch production of "the first mock examination with multiple pieces an

-

Why is engineering plastic used in the production of plastic toolboxes

2025-08-18The plastic toolbox is made of engineering plastics because the comprehensive performance of engineering plastics matches the core requirements of "protection, durability, and portability" of the toolbox. It can solve the shortcomings of ordinary plastics (such as polyethylene and polypropylene) in strength, weather resistance, etc. The specific advantages are as follows:

-

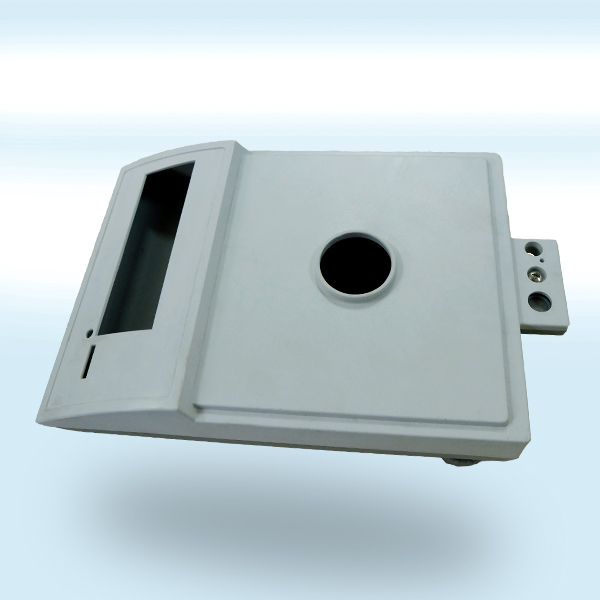

What are the advantages of toolbox molds

2025-08-11Toolbox mold is a key process equipment used for mass production of toolboxes. Its advantages are mainly reflected in production efficiency, product quality, cost control, and other aspects, as follows:

-

Why is the sealing of plastic storage boxes good

2025-08-04The good sealing of plastic storage boxes is mainly related to their material characteristics, structural design, and processing technology. The specific reasons are as follows: 1. The density of the material itself The commonly used materials for plastic storage boxes, such as PP polypropylene, PE polyethylene, PET polyester, ABS, etc., have a tight molecular structure and good barrier p

-

What are the applications of the insulation properties of plastic toolboxes in the medical field

2025-07-28Plastic toolboxes have important and widespread applications in the medical field due to their excellent insulation properties (non-conductive, non-conductive, and some materials also have chemical insulation properties), mainly reflected in the following scenarios:

Home

Home

Product

Product

Wechat

Wechat

Telephone

Telephone